Table of Contents

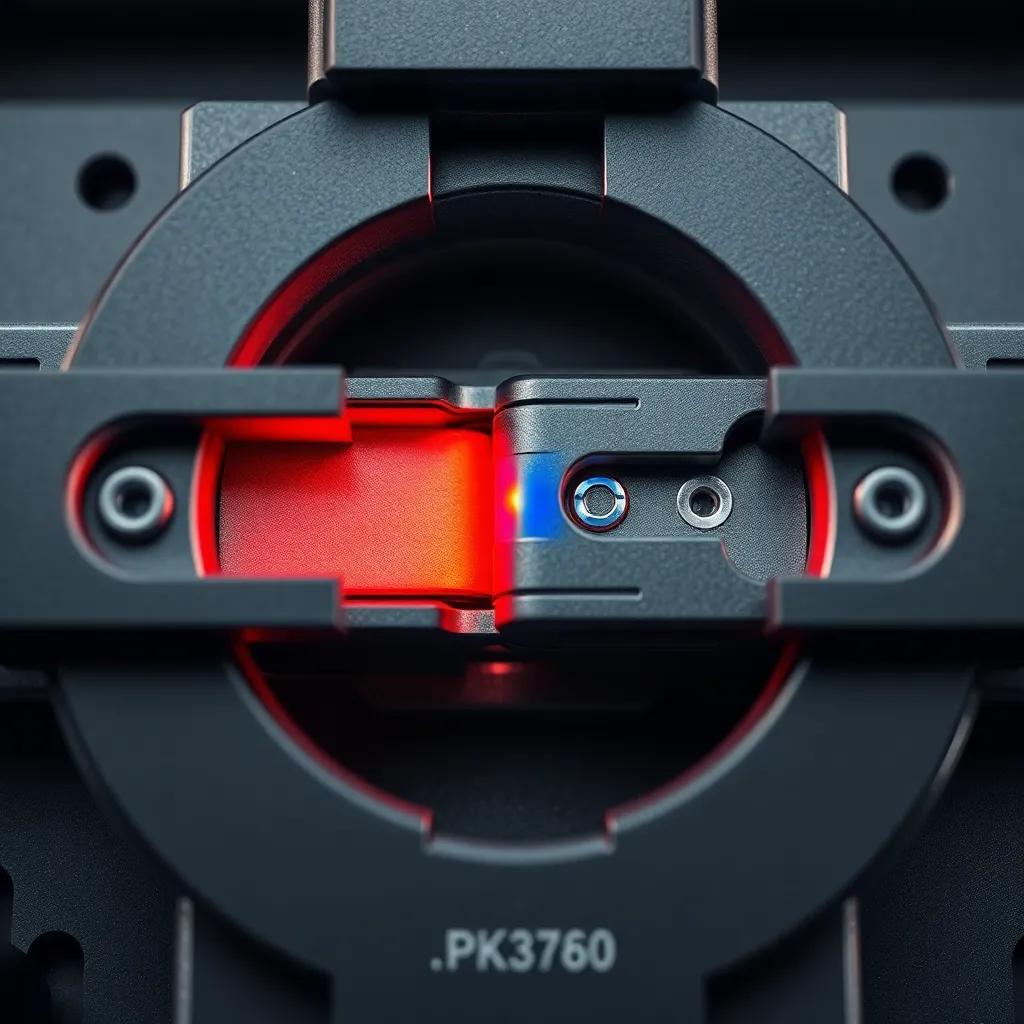

Hinge Heat Dilemma

Have you ever noticed how something as simple as a hinge can be the difference between success and failure in high-tech applications? Over 60% of manufacturers state that heat stress affects performance and lifespan of mechanical components. Recent studies by engineering firms show dramatic increases in efficiency when addressing thermal issues upfront. As industries rapidly innovate,it’s crucial to improve fold hinge designs to combat heat stress through advanced materials,innovative cooling techniques,and predictive analytics.

The Crucial Role of Materials

Advanced materials are redefining the capabilities of fold hinges by enhancing durability under extreme conditions. Customary metals often buckle or warp due to thermal expansion at high temperatures. Switching to engineered composites not onyl reduces weight but also improves longevity.

- Lightweight Composites: Compared to metal hinges which may withstand temperatures up to 150°C, carbon-fiber-reinforced polymers endure up to 200°C, increasing reliability.

- Thermal Conductivity Insights: Innovative ceramics exhibit low thermal conductivity (0.5 W/mK) compared to aluminum (205 W/mK), ensuring less heat is transferred during operation.

Implementing these modern materials has proven beneficial; as a notable example, an aerospace company reported a 25% increase in operational lifespan after adopting composite-based hinges. Thus, investing in better materials directly impacts efficiency and reduces maintenance costs substantially.

Cooling Techniques for Enhanced Performance

As we strive for excellence in niche applications, integrating effective cooling solutions becomes imperative. Cooling systems designed specifically for fold hinges can mitigate overheating risks that led to catastrophic failures.

A recent survey indicated that companies employing active cooling systems observed:

- A reduction in temperature spikes by 40%

- Improved energy efficiency by nearly 30%

Comparatively speaking, businesses without reliable cooling mechanisms faced breakdowns twice as frequently over similar periods. Utilizing designs like micro-channel coolers allows for greater control over thermal regulation-overcoming limitations posed by passive methods alone.

For example, a robotics firm transitioned from traditional lubricants prone to melting under high heat scenarios toward innovative nano-lubrication technology-resulting in continuous operations even at elevated temperatures while improving overall system responsiveness.

Implications Beyond Design

The implications of mitigating heat stress extend beyond mere design choices-they impact entire ecosystems within industries effectively utilizing fold hinges. From manufacturing plants experiencing lower downtime rates all the way through logistics networks optimizing fleet management strategies thanks largely due their enhanced machinery reliability-the benefits are expansive.

Industries leveraging technology adaptations report upwards of 15% growth year-over-year, as efficient mechanical parts improve production timelines drastically while maintaining safety protocols due thoughtfully-engineered designs resisting wear caused by excess heating elements present during complex operations alike automated assembly lines or aerospace innovations navigating turbulent atmospheric conditions with confidence built right into core functionality itself!

Innovation Ignites Progress

refining the design and execution of fold hinges amidst growing technological demands reveals vast opportunities across sectors dependent on precision mechanics. Taking action against thermal strains now prepares various industries for future advancements yet unseen!

Ultimately-a call remains clear-for every strategic decision made regarding component selection drives substantial value creation upward towards higher productivity levels altogether! How will your institution rise above challenges presented today?